ANUTRON-2108 UHMWPE

A HIGH ABRASION RESISTANT ENGINEERING PLASTIC

ANUTRON-2108 Ultra High Molecular-weight Polyethylene (UHMWPE) has polymer chains 10 to 20 times longer than High Density Polyethylene. The longer chains (higher molecular weight) give UHMWPE major advantages in toughness, abrasion resistance and freedom from stress cracking. ANUTRON-2108 shares the lubricity, chemical resistance and excellent electrical properties of conventional HDPE. ANUTRON-2108 has several extra-ordinary properties, particularly abrasion resistance (ten times better than carbon steel) and suitable for extremely low temperature applications (-250 C to 80 C); even when colder than liquid nitrogen. In the food processing industry, its self lubricating properties and resistance to boiling water are exploited. It complies with FDA requirements for handling food, water and pharmaceuticals. Many uses are based on its noise and shock absorbing properties. In mining industry, ANUTRON-2108 is used as liners in chutes and hoppers due to its excellent abrasion and chemical resistance.

Conveying of bulk materials via chutes, toughs, hoppers and Dumper Truck are often disrupted by cracking, bridging or freezing. These disruptions neutralise the advantages which are achieved by mechanical or automatic charging and conveyance of bulk materials. Interruption of materials flow can cause a lot of problems and expenses. These problems can be solved by using ANUTRON-2108 Linings.

The anti stick paraffin like slippery surface of ANUTRON-2108 has a very low coefficient of friction which makes it an ideal material for lines when handling cohesive bulk solids. This surface characteristic has a tendency to promote smooth flow of materials rather than obstruct it. Its zero moisture absorption reduces the problem of bulk solid freezing on its surface.

Due to extremely high molecular weight ANUTRON-2108 has excellent wear resistance properties including high impact strength, breaking strength and high abrasion resistance values

WHY YOU SHOULD SPECIFY ANUTRON-2108 ?

- Highest impact strength amongst all thermoplastics.

- Unmatched resistance to wear due to abrasion - out lasts stainless steel by a factor of 6 to 1..

- Excellent sound dampening properties - ideal for controlling environmental noise and pollution.

- Resistance to corrosion to all kinds of chemicals.

- Self lubracating.

- Zero water absorption - dimensionally stable.

- Paraffin like surface is anti-stick, cuts maintenance / cleaning costs.

- Light in weight - easy to handle.

- Good electrical insulation properties.

PHYSICAL PROPERTIES OF ANUTRON-2108

| Property | Unit | Test Method | Value |

|---|---|---|---|

| Density | g/cm3 | ASTM D792 | 0.94 |

| Water Absorption | % | ASTM | < .01 |

| Flammability | (3mm/6mm Thick) | UL 94 | HB |

| Yield Stress | kgf/cm2 | ASTM D638 | 200 |

| Elongation at Break | % | ASTM D638 | ˃200 |

| Tensile Module of Elestasity | kgf/cm2 | ASTM D638 | 6925 |

| Notched Inpact Strength(Charpy) | kj/m2 | ASTM D 256 | 83 |

| Hardness Durometer at 23 C | Shore D | ASTM D 2240 | 80--85 |

| Hardness Rockwell | Scale R | ASTM D 785 | 110 |

| Deflection temperature at 4.6Kgf/cm (66 psi) (HDT) | °C | ASTM D 648 | 155--165 |

| Maximum service temperature | |||

| Continuous | °C | 100-110 | |

| Intermittent | °C | 150 | |

| Melting Point | °C | ASTM D 3418 | 220 |

| Co-efficient of friction | ASTM D 3702 | ||

| against self | 0.40-0.50 | ||

| against polished steel dry | 0.25-0.30 | ||

| against polished steel initially lubricated | 0.15-0.25 | ||

| against polished steel lubricated | 0.08-0.15 | ||

| Dielectric Strength (short term 0.5mm thick) | Kv/mm | ˃12 | |

| Flammability | ASTM D 149 | Self Extinguishing |

TYPICAL APPLICATIONS

- Bearing Bushes

- Curved Guides

- Ropeway Tyres

- Bearing Blocks

- Guide Bushes

- Sliding Blocks

- Bearing Segments

- Gears

- Sealing Rings

- Bottle Infeed Stars

- Gear Racks

- Sliding Plates

- Chain Sprockets

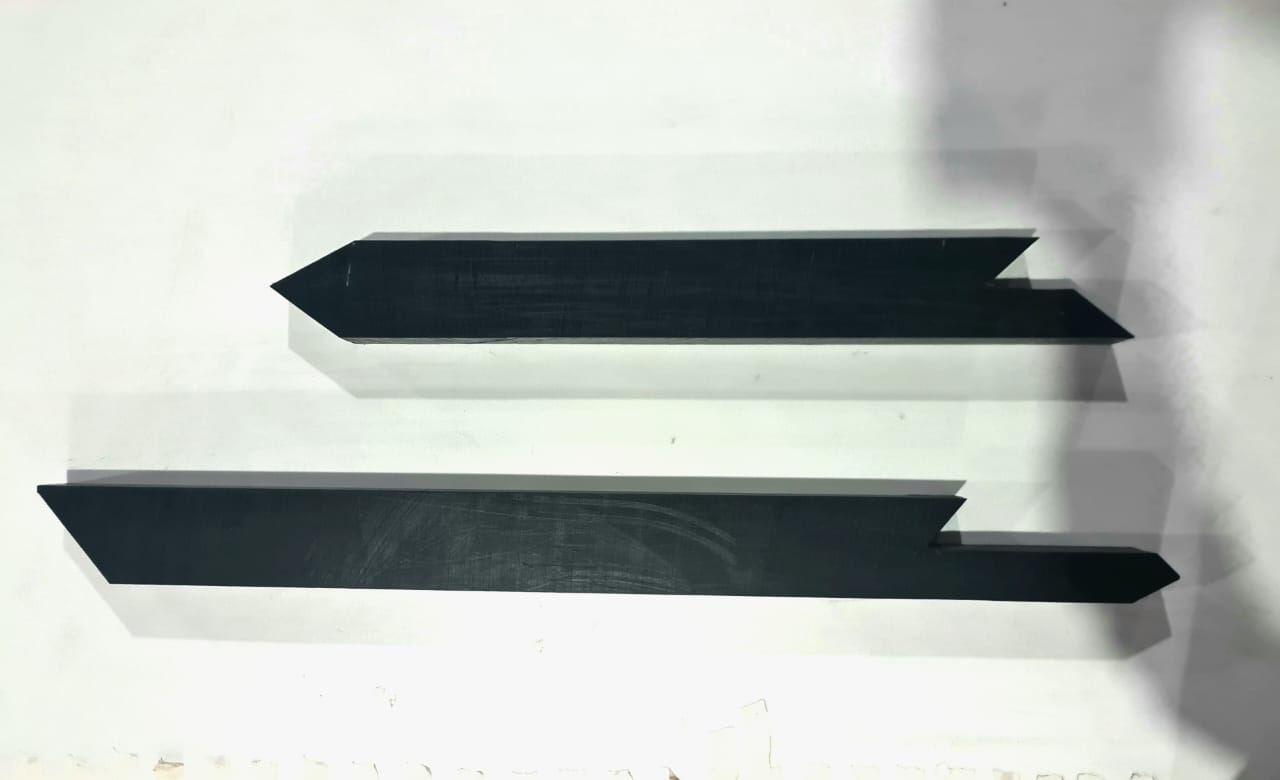

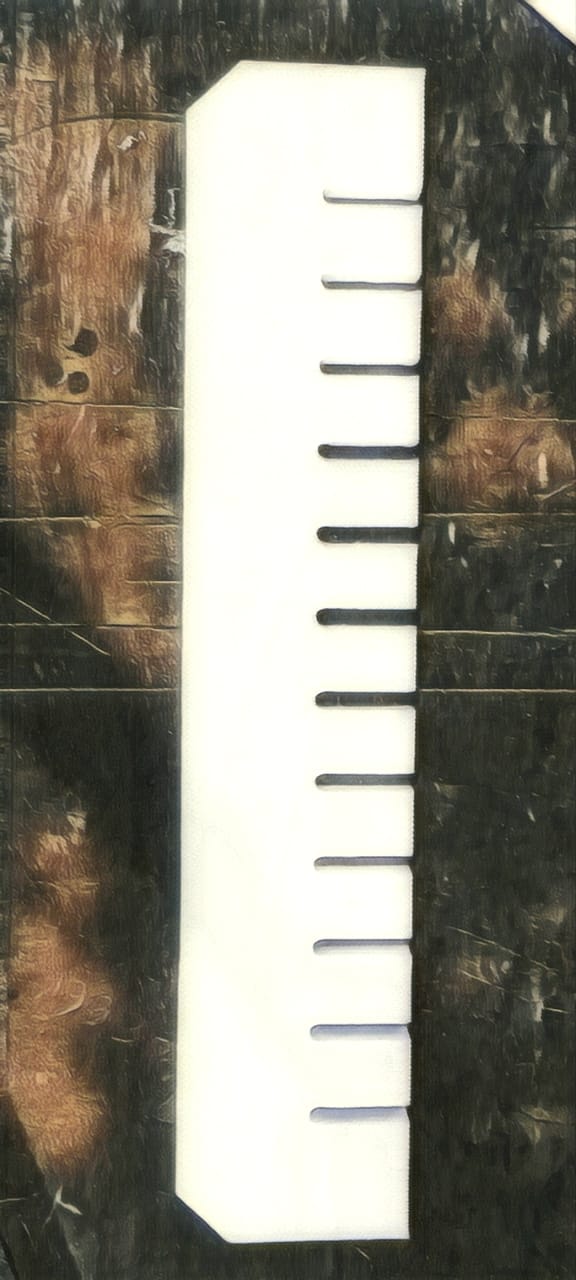

- Protection Strips

- Slipper Pads

- Conveyor Links

- Pulleys

- Thrust Washers

- Cams

- Picking Cones

- Valve Seats

- Rollers

- Cutting & Stamping Plates

- Wear Strips