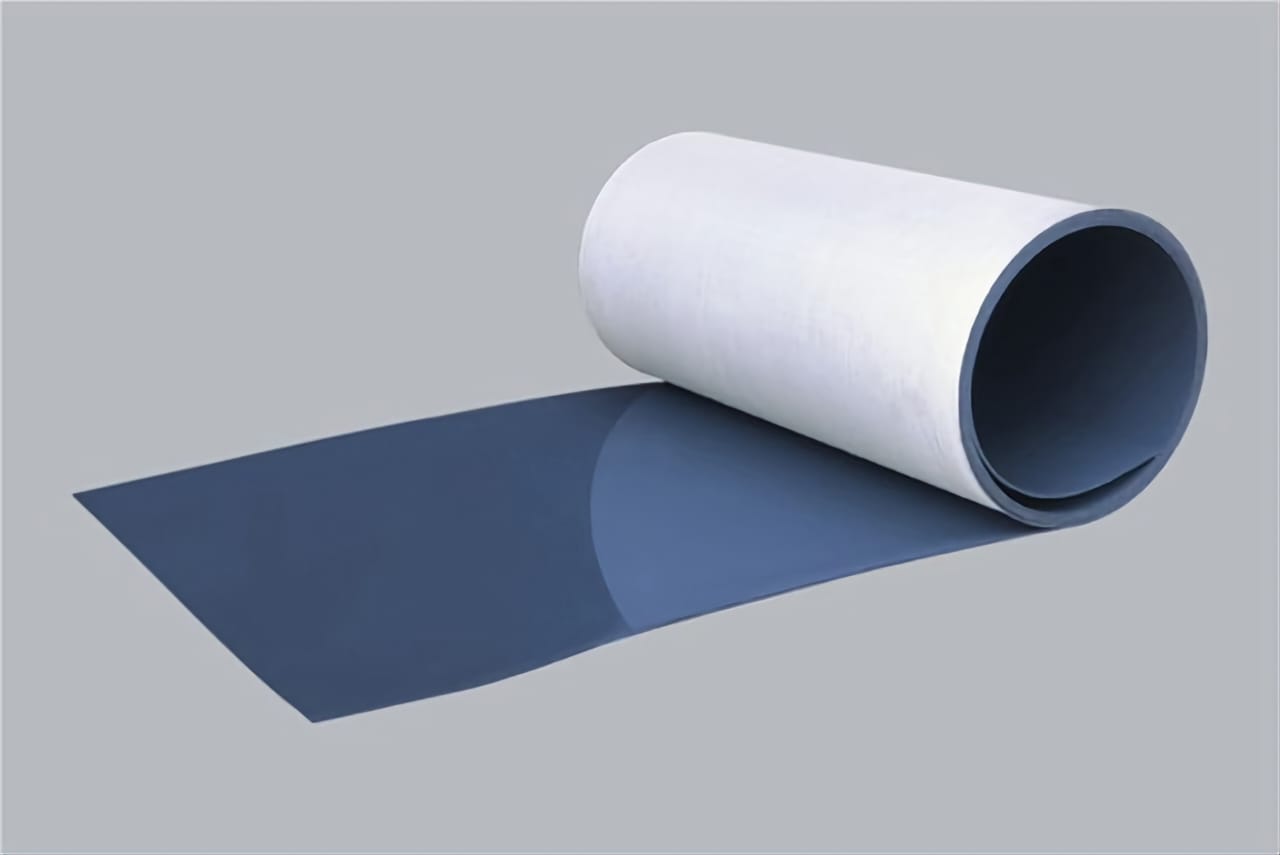

ANUTRON-1616 POLYPROPYLENE

AN EXCELLENT CHEMICAL RESISTANCE THERMOPLASTIC

ANUTRON-1616 Polypropylene is one of the most versatile type of plastic which belongs to polyolefin group. It is partially crystalline and non-polar polymer. This light weight material with its toughness also hold flexibility that opens its route for various application. ANUTRON-1616 can be moulded, extruded or compressed to give its desire shape. It can also be tailored to fabrication methods such as, welding, machining, thermoforming, vacuum forming which further pave its way for various industrial applications. ANUTRON-1616 has excellent chemical resistance properties that opens its way for processing and storage tanks. This Non-Toxic food grade material with high impact resistance find a wide range of application in food- processing, orthoptics and leather industries

ANUTRON-1616 comes in different grades as Co-polymer, Homo-polymer, Random Co-polymer, High temperature grade to suit its perfect application.

ANUTRON-1616 is available as stock item in basic shapes (Rods, Sheets, Blocks, Squares and Rectangular Bars) with machining instructions. It is also available as Pipe, Fittings, Valves

WHY YOU SHOULD SPECIFY ANUTRON-1616 ?

- Excellent Chemical Resistance

- Excellent Corrosion Resistance

- Light Weight

- Low Coefficient of Friction

- Very Good Toughness and Resilience

- Outstanding Resistance to repeated Impacts

- Low Noise Factor

- Excellent Weldability

- Excellent Weldability

PROPERTIES OF ANUTRON-1616

| Property | Unit | Test Method | Value |

|---|---|---|---|

| Specific Gravity | gm/cc | ASTM D 792 | 0.91-0.92 |

| Tensile strength | Kgf/cm² | ASTM D 638 | 250-450 |

| Elongation at Yield | % | ASTM D 638 | 50-600 |

| Compressive Strength | Kgf/cm² | ASTM D 695 | 550-750 |

| Modulus of Elasticity (Dry) | Kgf/cm² | ASTM D 638 | 13,000 |

| Bending Strength | Kgf/cm² | 450 | |

| Impact strength | No-Break | ||

| Impact strength (Izod Notch) at 23 C | KJ/m² | ASTM D 256 | 5 |

| Water Absorpion for 24 hrs | % | ASTM D 638 | <0.01 |

| Hardness Durometer at 23 C | Shore D | ASTM D 2240 | 71 |

| Co-efficient of friction | ASTM D 3702 | ||

| against steel dry | 0.5 | ||

| Softening Point Vicat | °C | ASTM D 1525 | 150 |

| Melting Point | °C | ASTM D 3418 | 160 |

| Maximum service temperature | |||

| Continuous | °C | 90 | |

| Intermittent | °C | 100 | |

| Co-efficient of Linear Expantion | (per °C) x 10⁶ | ASTM D 696 | 160 |

| Thermal Conductivity | Cal/Sec/cm/°C x10ˉ4 | ASTM C 177 | 3.3 |

| Specific Heat | 0.46 | ||

| Flammability | Cal / °C/ gm | ASTM D 635 | Slow |

| Dielectric Constant | 106 Cycle/Sec | ASTM D 449 | 2.0 |

| Dielectric Strength | Kv/mm | ˃8 | |

| Volume Resistisity at 50% RH | Ohms/cm | ASTM D 527 | >10¹6 |

| Dissipating (Power) Factor | 108 Cycle/ sec | ASTM D 150 | <0.0002 to 0.0003 |

TYPICAL APPLICATIONS

- Chemical Storage Tank

- Prosthesis

- Chopping Board

- Pickling Tank

- Orthosis

- Cutting Boards

- Electroplating Tank

- Calipers

- Rolling Pin

- Electroplating Barrel

- Sockets

- Rolling Plate

- Liners

- Pilon

- Sprockets

- Rack

- Loops

- Washers

- Gratings

- Pipe & Fittings

- Nut & Bolts

- Filters

- Valves

- Brackets