ANUTRON-1621 POLYURETHANE (PU)

A HIGH ABRASION RESISTANCE ENGINEERING PLASTIC

ANUTRON-1621 Polyurethane Elastomer components possess outstanding tensile strength and modulus of engineering properties for industrial applications. The inherent strength and ingrained superiority of ANUTRON-1621 make it most appropriate for demanding industrial (mechanical, chemical, thermal & electrical) applications.

Its high coefficient of friction leads to versatile applications in frictional drives. Its good electrical & thermal properties, resistance to chemical media and wide working temperature range give the additional characteristics to its application.

Its excellent abrasion resistance together with very high impact & tensile strength and tough tear strength make ANUTRON-1621 versatile for engineering application.

Depending upon the application, ANUTRON-1621 can be formulated to exhibit low or high resilience and wide range of hardness.

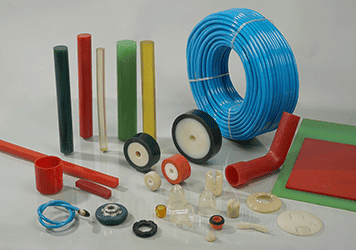

ANUTRON-1621 is available in form of rods, sheets, square and rectangular bars tubings, machined , moulded and fabricated components

WHY YOU SHOULD SPECIFY ANUTRON-1621 ?

- Exceptional wear and abrasion resistance

- High Impact Strength

- High Elasticity

- Low coefficient of friction

- Wide Resilience

- Excellent Hydrolysis Stability

- Noise & Vibration Dampening

- High Tensile Strength

- Resistance to Grease, Lubricants, Oils and Chemicals

PROPERTIES OF ANUTRON-1621

| Property | Unit | Test Method | Value |

|---|---|---|---|

| Specific Gravity | gm/cc | ASTM D 792 | 1.18 - 1.20 |

| Tensile strength | Kgf/cm² | ASTM D 638 | 400 |

| Elongation at break | % | ASTM D 638 | 500 |

| Compression Strain Rest (At Ambient Temperature) | % | ASTM D 695 | 20 |

| Tear Strength | N/mm² | ASTM D 395 | 60 |

| Shore Hardness | Shore A | ASTM D 2240 | 85-95 |

| Abrasion | mm² | ASTM D 5963 | 50-55 |

| Linear Dilation Coefficcient | 10ˉ⁶K | 20-50°C | 200 |

| Maximum service temperature | 20-100°C | 190 | |

| Continuous | °C | 90-100 | |

| Intermittent | °C | 130 | |

| Melting Point | °C | ASTM D 3418 | 200 |

| Heat Condictivity | W/m.k | 0.291 | |

| Specific Heat Capasiry | Kj/Kg.K | 20-100°C | 1.88 |

| Thermal Resictance | °C | 0.75 | |

| Dielectric Strength (short term 0.5mm thick) | Kv/mm | ˃12 | |

| Notch Resistance | N/cm | ASTM D 470 | 124 |

TYPICAL APPLICATIONS

- Bucket Liners

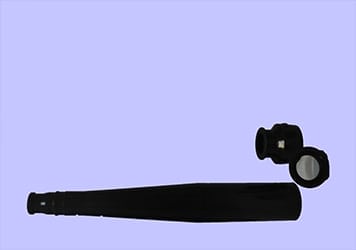

- Nozzles

- Friction Wheel

- Conveyor Rollers

- Rollers

- Idler Rollers

- Scraper Blades

- Wheels

- Pads

- Bushing

- Discharge Nozzle

- Spider Coupling

- Pump Lining

- Water Scrapper

- Drive Rollers

- Pipe Lining

- Pulp Paddles

- Coil Coasting Rolls

- Impellers

- Bumper Blocks

- Hopper Lilers

- Guide

- Wiper

- Ram Packing

- Ropeway Types

- Muff Coupling

- Chute Liners

- CentriCleaner cone

- Pallet Truck Wheels

- Shock Absorber